Propane

Propane, also known as liquefied petroleum gas (LPG) or propane autogas, has been used worldwide as a vehicle fuel for decades. It is produced as a byproduct of natural gas processing and crude oil refining. Propane is stored as a liquid, and fueling infrastructure is widespread.

Watch our webinars: Autogas Answers, Road Ranger Propane Conversion and Propane for Paratransit

Propane, or liquified petroleum gas (LPG), is an alternative fuel used to power light-, medium- and heavy-duty propane vehicles. Propane accounts for two percent of energy use in the U.S., less than three percent of which is used for transportation. It occurs as a gas at standard temperature and pressure, but is compressed and liquified for use as a fuel. Propane is produced as a by-product of natural gas processing and crude oil refining. Interest in LPG as a fuel stems from its clean-burning qualities, high-energy density, domestic availability, and relatively low cost, making it the world’s third most common transportation fuel behind gasoline and diesel.

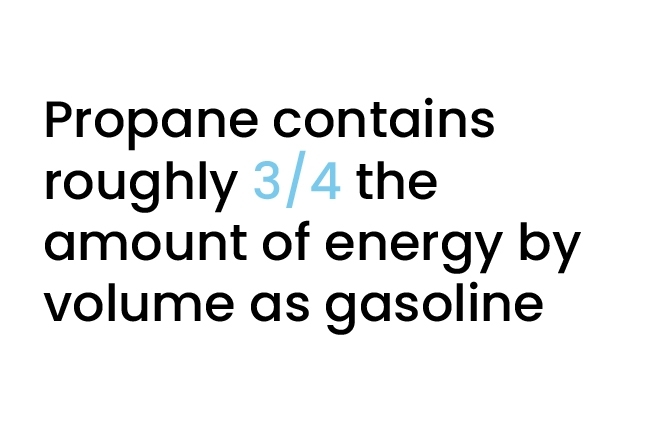

There are two types of propane vehicles: dedicated, which run on propane only, and bi-fuel, which may run on both propane and gasoline. Because propane fuel has a lower energy density than gasoline, the fuel economy of propane vehicles is lower. However, this is offset its lower per-gallon cost and lower maintenance costs. Propane vehicles produce tailpipe emissions comparable to gasoline and diesel vehicles but reduce life cycle GHG emissions by nearly 13%.

Although propane is most often used in medium- to heavy-duty applications, light-duty vehicles are also available. However, propane is not currently widely available as an alternative to diesel engines. Propane vehicles cost more than their gasoline counterparts, with investment predicated on life cycle fuel cost savings.

Propane fueling infrastructure is like gas or diesel, consisting of a fuel tank, pump and dispenser. Extra safety equipment is required to dispense the compressed fuel safely. There are eight public LPG fueling stations in North Florida, predominantly centered in Duval and Clay counties. Propane marketers typically provide private fueling infrastructure to fleets relatively inexpensively as part of a long-term fuel purchase agreement.

Renewable propane is produced from biomass feedstocks such as cooking oil, animal fats and 20% dimethyl ether produced in biodiesel refineries. Chemically identical to propane, renewable propane may replace or be blended with propane in all applications. Production is anticipated to align with the increasing output of renewable diesel and sustainable aviation fuels, as renewable propane can be generated as a byproduct. The primary advantage of renewable propane over conventional is its lower carbon intensity and environmental impact. Overall carbon reduction benefits, however, depend on the feedstock used to produce the fuel. Research to reduce implementation barriers such as feedstock production and cost is ongoing.

Learn how the First Coast Road Rangers transitioned to bi-fuel propane, saved on fuel costs, and were able to provide employees pay increases and medical insurance.

The Putnam County School District, Student Transportation of America and KIPP Jacksonville have school buses fueled by propane autogas. Propane provides students with a cleaner, quieter and healthier travel experience compared to traditional diesel buses, while saving on fuel costs. Learn more about propane school buses.